Automation in Production Systems

Summary:

Automation in production systems involves both the automation of manufacturing systems in factories and the computerization of manufacturing support systems. Automated manufacturing systems perform operations such as processing, assembly, inspection, and material handling with reduced human participation. These systems can be classified into fixed automation, programmable automation, and flexible automation. Computerized manufacturing support systems reduce the manual and clerical effort in product design, manufacturing planning and control, and business functions.

Companies automate production systems for reasons such as increasing labour productivity, reducing labour costs, mitigating labour shortages, eliminating routine tasks, improving worker safety, enhancing product quality, reducing manufacturing lead time, accomplishing processes impossible to do manually, and avoiding the high costs of not automating. Automation in manufacturing provides significant competitive advantages and can lead to improved quality, higher sales, better labour relations, and a better company image.

Excerpt:

Automation in Production Systems

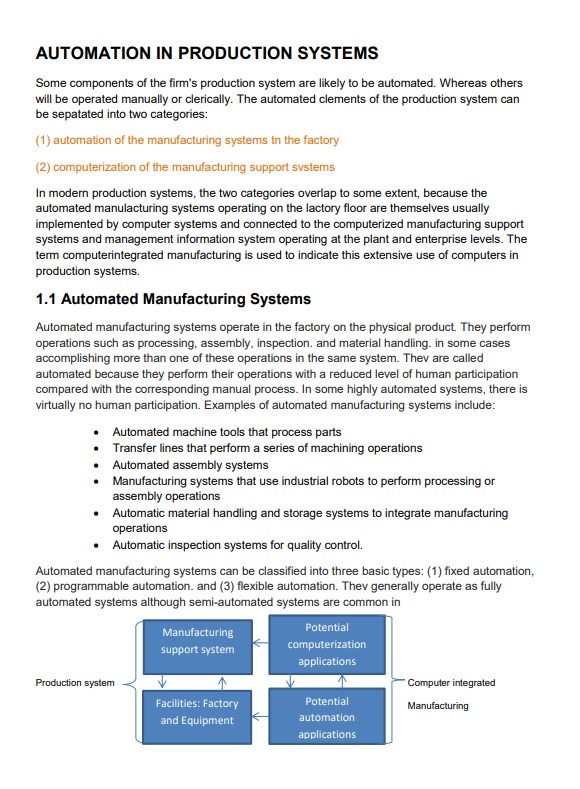

Some components of the firm’s production system are likely to be automated. Whereas others will be operated manually or clerically. The automated elements of the production system can be separated into two categories:

(1) automation of the manufacturing systems in the factory

(2) computerization of the manufacturing support systems

In modern production systems, the two categories overlap to some extent because the automated manufacturing systems operating on the factory floor are usually implemented by computer systems and connected to the computerized manufacturing support systems and management information systems operating at the plant and enterprise levels. The term computer integrated manufacturing is used to indicate this extensive use of computers in production systems.

1.1 Automated Manufacturing Systems

Automated manufacturing systems operate in the factory on the physical product. They perform operations such as processing, assembly, and inspection. And material handling. In some cases accomplishing more than one of these operations in the same system. They are called automated because they perform their operations with reduced human participation compared with the corresponding manual process. In some highly automated systems, there is virtually no human participation.

Reviews